The apparel industry can hardly ever be completely responsible, but at North Outdoor we believe that every player in the field has a responsibility to strive for better. For us, responsibility means continuous learning, development, and courageous choices – from establishing our domestic knitting mill to close cooperation with our international production partners.

Every step towards more sustainable solutions, such as more transparent production or lower emissions, strengthens our mission to offer products we can be proud of. We are guided by values of courage, authenticity, and naturalness – in everyday life, decisions, and also in design.

PRODUCTION CHAIN

FINLAND

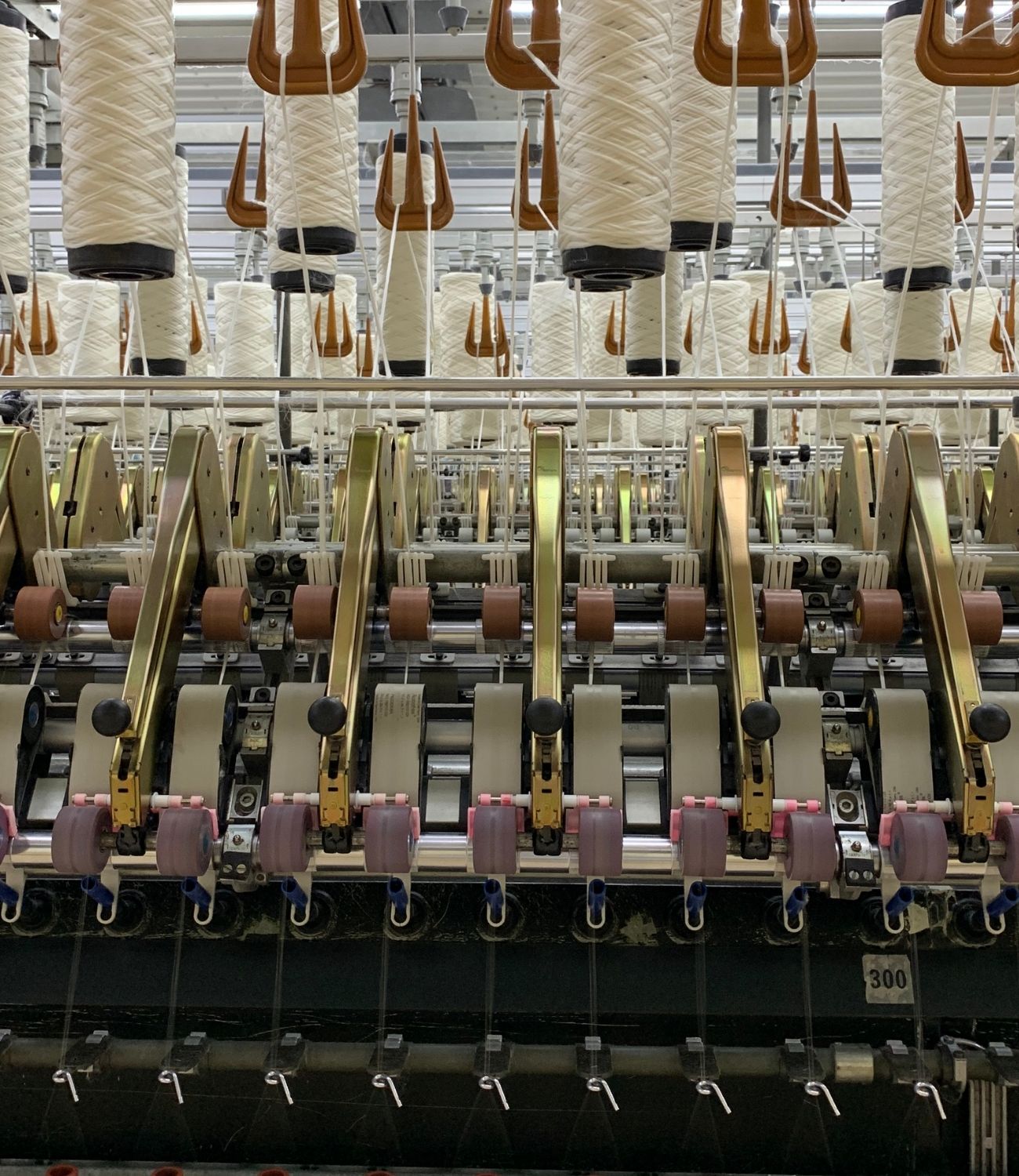

All knitwear products are made in Finland, in our own knitting mill in Rusko, Oulu. We built the knitting mill in 2021 to ensure the responsibility and first-class quality of our products. The modern knitting mill is exceptional by Finnish standards: 3D knitting machines knit products directly into their final shape, which significantly reduces waste and scrap.

The merino wool yarns we use come from the Italian Lanerossi Filati, whose production chain from wool to yarn takes place within the EU, mostly in Lithuania. The mulesing-free wool used for the yarns comes from South America and South Africa. Lanerossi Filati's yarns are Woolmark certified and OEKO-TEX® Standard 100 certified.

Our products made in Finland have been awarded the Key Flag symbol, and we also offer a 100-day satisfaction guarantee as proof of uncompromising quality and appreciation for Finnish craftsmanship.

CHINA

A large part of our products, such as base layers, knitwear products, shell jackets, and socks, are manufactured in China by long-term and carefully selected partners. We have worked with the same factories for years, and to ensure responsibility, we maintain close cooperation on site: we regularly visit the factories, and in addition, we have a local employee who maintains daily contact with production. This enables direct dialogue and quick response at all stages of production.

Amfori BSCI

We monitor all the Chinese factories we use through the international, independent amfori BSCI system. We audit each factory annually by a third party and closely follow the audit results. Based on the audit, a development plan is created, and we actively influence the improvement of working conditions and responsible operational models.

The collaboration has yielded concrete results: the largest manufacturer of our merino wool products, responsible for over 70% of the products made in China, improved from a C level to a B level in the 2024 BSCI audit. This is a significant achievement, as only 7.5% of Chinese factories reach this level. Improvements in working conditions and environmental impact management are the result of our long-term, goal-oriented cooperation. Additionally, in July 2024, the same manufacturer implemented a solar power plant on the factory roof, which currently covers 100% of the factory's annual electricity consumption. This investment is a tangible step towards a smaller carbon footprint and demonstrates our manufacturer's commitment to long-term sustainable solutions.

The average score of the other factories we use in amfori BSCI audits is C (acceptable), but their results in specific areas are mostly at A (very good) and B (good) levels. Lower scores are mainly due to seasonal overtime, which is voluntarily requested by the workers themselves and compensated appropriately. This is not forced labor, but voluntary, legally paid overtime.

The yarns we use mainly come from the German Südwolle Group, the world's largest supplier of pure wool yarn. The company is known for its strong commitment to environmental responsibility, employee well-being, and social sustainability. The yarns are spun in Zhangjiagang, only about half an hour away from the knitting mills and sewing factories, enabling efficient and environmentally friendly production. The yarns are Woolmark labeled and OEKO-TEX® Standard 100 certified. The yarn for shell jackets and caps made from woven fabric is spun directly at the fabric manufacturer. The origin of the wool in all products made in China is Australia, and it is always purchased mulesing-free.

We carefully select our production partners. In China, we can combine responsible production, high quality, and delivery reliability in a way that supports both sustainable development and innovative product development. Transparency and continuous improvement are at the core of our operations – even when production takes place farther away.

LITHUANIA

We have recently expanded our production to Lithuania as well. Our Lithuanian partner manufactures wool fleece jackets and accessories from recycled wool blend knitwear supplied by the Italian company Pontetorto. Pontetorto is known for its innovative product development as well as responsible and ecologically sustainable production. The recycled wool is made from consumer waste, supporting the circular economy and reducing environmental impact.

In Lithuania, the necklines of some of our knitwear products are also finished using a special technique that our own knitting machines are not yet capable of. However, the actual knits are produced in our own factory in Oulu, and in Lithuania only the neckline finishing and product packaging are done. This ensures that the majority of the manufacturing process of these knits remains in Finland, maintaining the highest possible domestic content level.

Animal welfare is an important ethical issue in merino wool production. North Outdoor uses only mulesing-free wool sourced from farms where animal welfare is given special attention. Depending on the product, the wool we use comes from South America, South Africa, and Australia. These are regions where high-quality wool can be produced responsibly.

Like all animal-derived materials, merino wool production generates emissions. Sheep digestion produces methane, and extensive grazing in some areas can lead to soil degradation and erosion. These factors impact climate change.

The carbon footprint of wool is, however, difficult to assess unambiguously. If wool is a by-product of meat production, its emissions are distributed among several products and thus smaller. Conversely, if wool is the primary production purpose of the animal, its share of the environmental load increases.

It is worth noting that wool accounts for only about 1–2% of the world’s total fiber production. For comparison, polyester accounts for over 50% and cotton about 25%. Therefore, wool’s overall impact on a global scale is relatively small – especially when considering wool’s long lifespan, recyclability, and biodegradability.

One challenge of merino wool products is the long supply chain: wool can travel through several countries before reaching the customer as a finished product. North Outdoor aims to minimize this burden by concentrating production processes as closely as possible in the same regions. For example, a large portion of our products made in China are spun, knitted, and finished geographically close to each other, reducing unnecessary transportation.

CHEMICALS

Merino wool is often chemically treated to make it machine washable (e.g., Superwash treatment). Such processes may use substances harmful to the environment unless carried out responsibly. The yarns used by North Outdoor from Südwolle Group are dyed and finished with non-toxic and environmentally friendly substances. The yarns we use in Oulu knitting mill products are untreated but withstand gentle machine washing on wool or hand wash programs.

Product labels